Finite Element Analysis (FEA) has a reputation for exclusivity. It’s often treated as a dark art — something reserved for OEMs and aerospace firms with server farms and dedicated PhDs.

That perception quietly costs small teams real money: overbuilt parts, wasted material, and prototype iterations that could have been avoided with a bit of insight earlier in the design.

But the physics hasn’t changed. The principles aren’t locked behind corporate firewalls. With modern tools and practical engineering judgment, small shops — even solo engineers — can use FEA to make better decisions, faster.

What FEA Really Is — and Isn’t

FEA is not magic, and it’s certainly not a replacement for engineering judgment. It’s a numerical approximation method: a way of breaking a part into many small elements and calculating how each reacts under load.

The math is complex, but the goal is simple:

See where it bends before you build it.

Where people go wrong is treating FEA like a “truth machine.” Every result depends on your assumptions:

- How the part is constrained

- How the load is applied

- Whether the material properties are realistic

- And only then, how the mesh is constructed

Garbage in, garbage out. But good engineering in, and FEA gives insight that can save weeks of iteration.

The Myth of the Million-Dollar Simulation

Twenty years ago, meaningful FEA really did require expensive licenses and heavy computing hardware. Today, that barrier has largely disappeared.

Built-in CAD solvers, cloud platforms, and open-source tools have democratized analysis. What once demanded a six-figure investment can now be done on a capable workstation or via subscription.

The bottleneck is no longer the software — it’s knowing how to ask the right question.

Start Simple — Validate Often

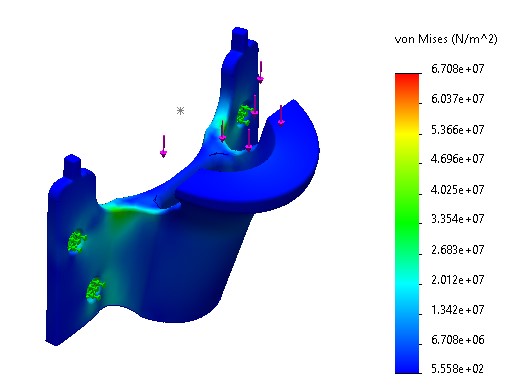

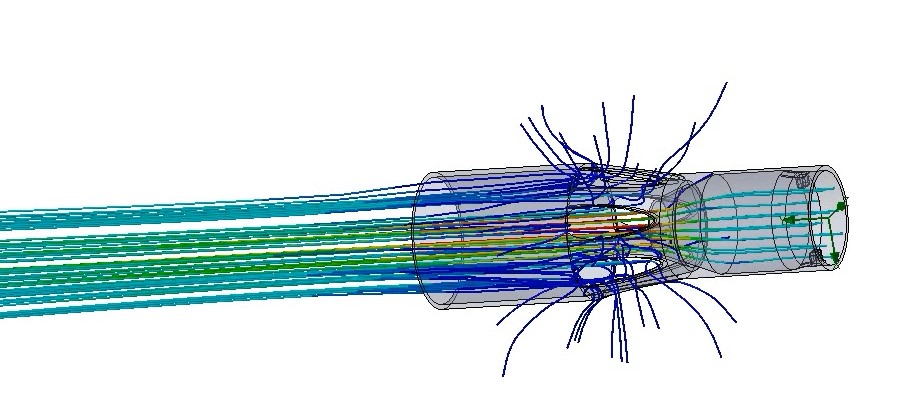

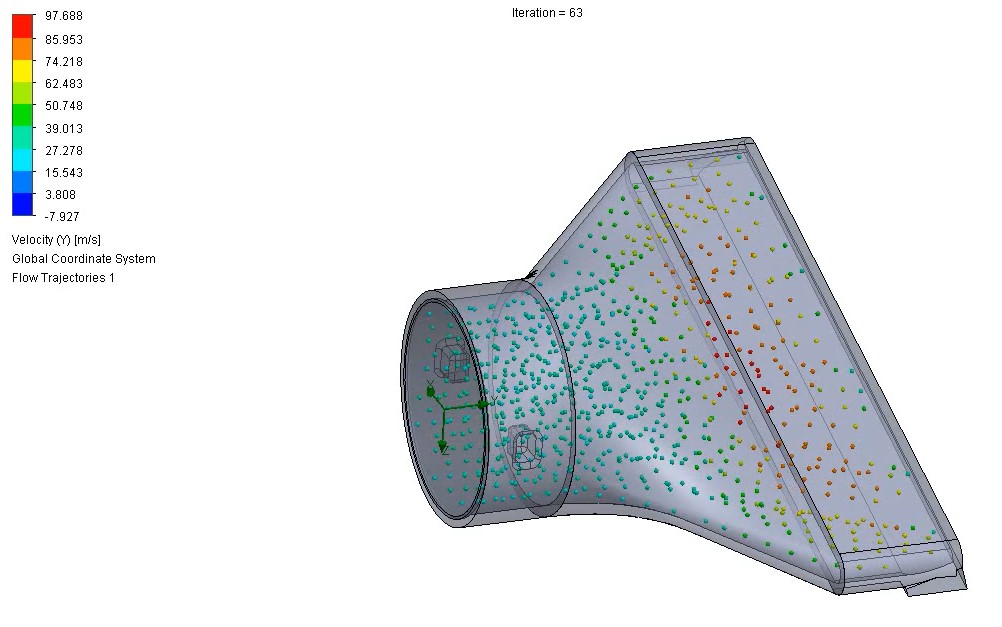

For small shops, FEA isn’t about impressing clients with rainbow plots. It’s about using simulation as a design lens — a way to de-risk decisions before cutting metal or printing parts.

Before you hit “run,” think like a tester:

- The goal: What specific question am I answering?

- The reality check: How would I validate this physically?

- The efficiency: What’s the simplest load case that reveals the failure mode?

A coarse-mesh, linear static study can often tell you whether a bracket is flirting with yield or a fixture is overbuilt. Save nonlinear contact and advanced material models for when there’s a clear reason to use them.

Tools, Rules, and Practical Trade-Offs

- Mesh is resolution: Don’t chase triangles; chase convergence.

- Anchors matter: Boundary conditions are your truth anchors — model the real world, not idealized fixtures.

- Materials are specific: Aluminum 6061-T6 is not “just aluminum.” Yield and modulus matter.

- Validate your gut: A quick hand calculation is still the fastest sanity check available.

There’s always a trade-off between speed and fidelity. The goal isn’t perfection — it’s enough confidence to make the next decision intelligently.

FEA as a Design Tool, Not a Checkbox

At Kotatsu, we treat FEA as part of the creative process, not just a final verification step. Used early, it nudges designs toward cleaner load paths, simpler structures, and better use of material — when changes are still cheap.

This is the difference between a verification mindset (“prove it works”) and a design mindset (“shape it so it can’t fail easily”).

When used this way, FEA stops being a corporate luxury and becomes what it always should have been: an amplifier for engineering intuition.

Bring Simulation to Your Shop

If you’re already designing in CAD, you’re most of the way there. The remaining gap is choosing the right level of analysis, setting up repeatable studies, and interpreting results honestly.

Kotatsu helps fabrication shops, research labs, and small product teams integrate FEA into real-world workflows — without the overhead or intimidation factor.

Advanced engineering doesn’t have to be inaccessible.

Kotatsu Design & Development Inc.

Kotatsu Design & Development Inc.